-

HOME

-

PRODUCTS

- Structured Light 3D Camera

-

High-Cost-Performance 8M, 16M, 25M Multi-Light Source Systems

-

Ultra-high Speed 21M Multi-optic System

-

RINDO HRDOF Series

-

Rindo HR Series 65M Multi-Light System

-

RINDO HS Series

- High Speed Area Scan Camera

-

COAXPRESS SERIES-29MM CXP 1LANE SERIES

-

COAXPRESS SERIES-40MM CXP 1LANE SERIES

-

COAXPRESS SERIES-60MM CXP 4LANE SERIES

-

COAXPRESS SERIES-70MM CXP 4LANE SERIES

-

PIXEL SHIFT

-

SWIR Area Array Camera

-

Camera Link Series

-

BC-GM(C)10M/14M/21M/OM(C)25M12X4

-

SOLUTIONS

-

SUPPORT

-

ABOUT US

-

CONTACT

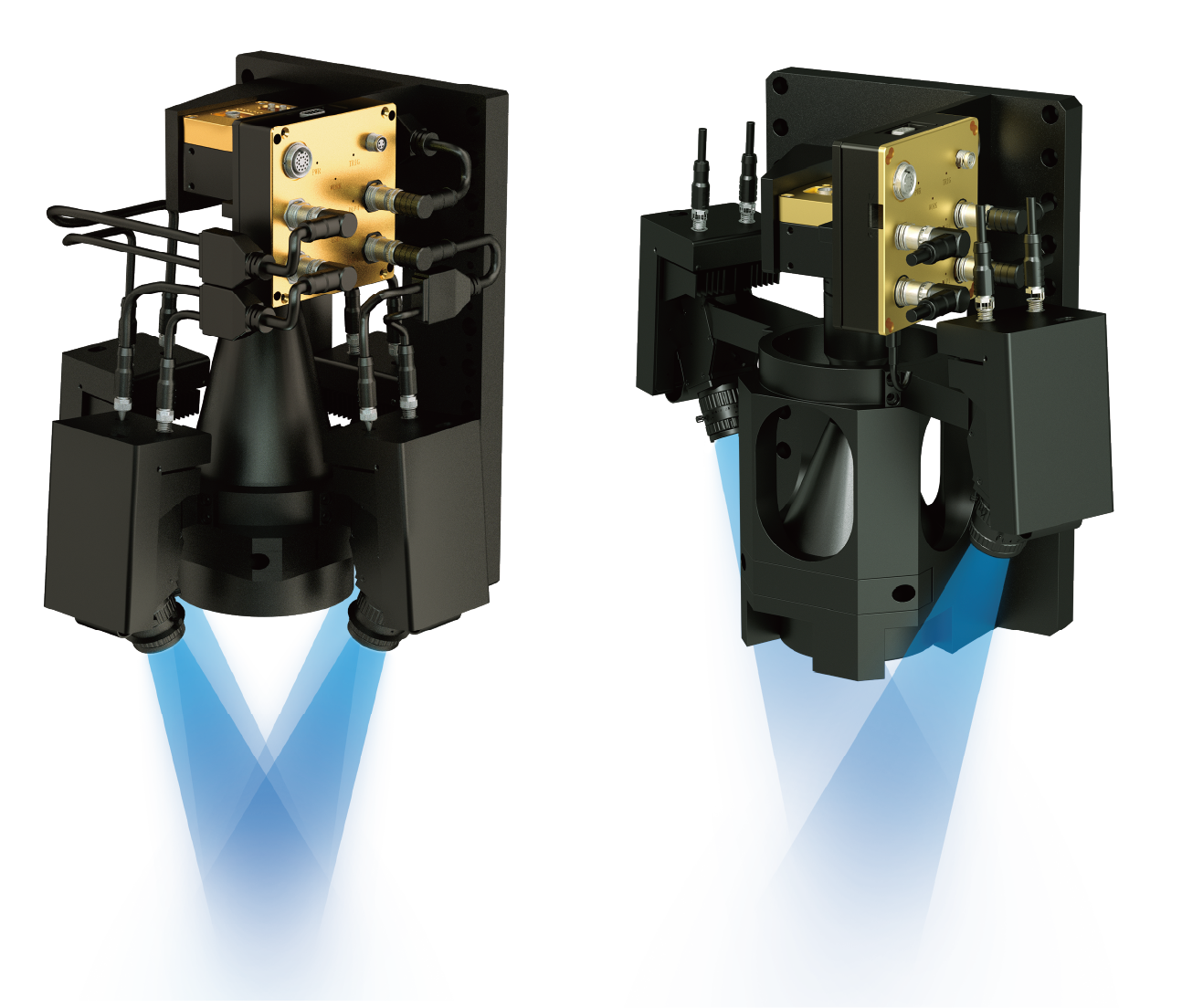

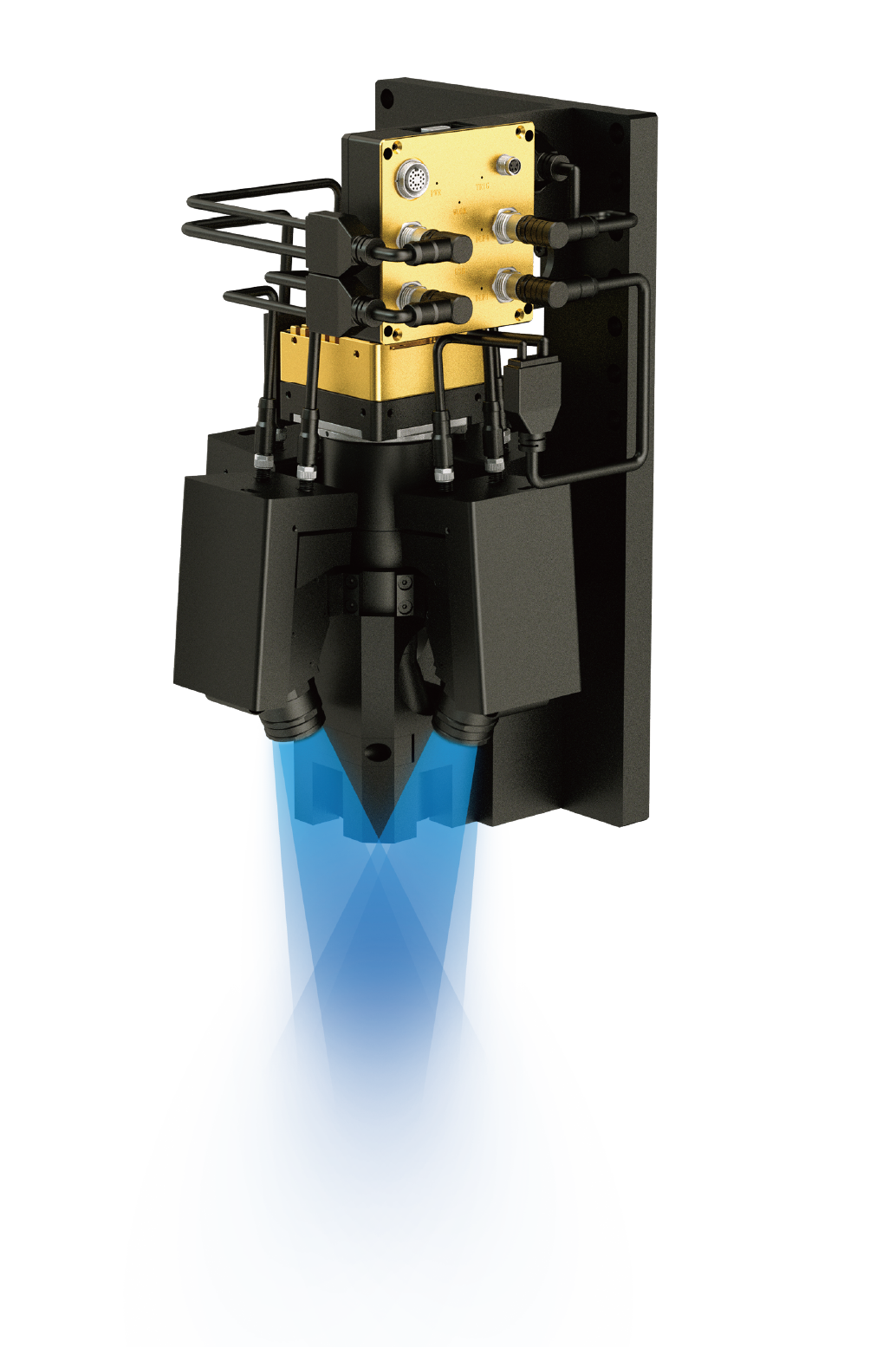

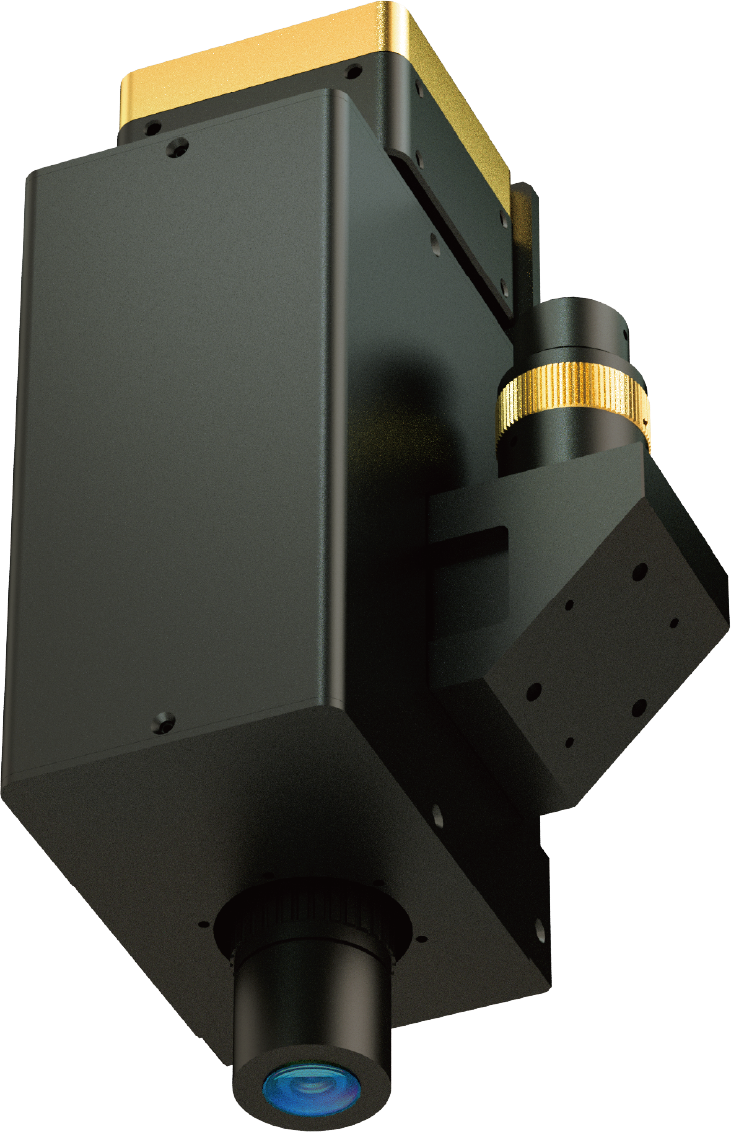

RINDO HRDOF Series

The RINDO HRDOF Series introduces the new 21M model, which retains the series' ultra-depth-of-field technology advantages while further expanding single-acquisition field of view coverage. This achieves a synergistic improvement in both large FOV and high precision, significantly increasing inspection throughput per unit time.

Suitable for high-precision 3D inspection of semiconductor wire bonding—including gold wire loop profiles and solder ball morphology—the model's expanded large FOV capability also enables efficient dimensional measurement and appearance inspection of precision 3C components (such as curved surface profile tolerance and complex geometries), providing flexible vision solutions for precision manufacturing across multiple industries.

Suitable for high-precision 3D inspection of semiconductor wire bonding—including gold wire loop profiles and solder ball morphology—the model's expanded large FOV capability also enables efficient dimensional measurement and appearance inspection of precision 3C components (such as curved surface profile tolerance and complex geometries), providing flexible vision solutions for precision manufacturing across multiple industries.

Features

- Upgraded Inspection Speed – Engineered for high-speed inline detection

- Algorithm Optimization – Significantly enhanced Z-axis repeatability

- Ultra-Large Depth of Field – Stable performance on complex surfaces

- Application-Optimized – Specifically tailored for semiconductor wire bonding and precision component dimensional measurement

- DLP

-

All 1280×720 912×1140 1920×1080

More >

- CMOS Resolution

-

All 3M 5M 12M 25M 65M

More >

- Xy Resolution

-

All <5μm <10μm <20μm <50μm <100μm <500μm <1000μm

More >

- Z-Axis Repeatability

-

All <5μm <10μm <20μm <50μm <100μm <500μm <1000μm

More >

- Frame Rate

-

All <=2.5 <=7.5 <=15

More >

- Light Source

-

All Default White Light Default Blue Light

More >

- Interface

-

All GigE USB_3.0 CXP

More >

Expand

- CONTACT INFORMATION

-

Address: 6 / F, Jingdong Technology Building, 76 Zhichun Road, Haidian District, Beijing / 2nd Floor, Building 7, Fengchuang Technology Park, Keji 13th Street Beijing Economic-Technological Development Area, Beijing

Telephone: 010-64754979

- Sales Consulting

-

E-Mail:

overseas@bopixel.com

Telephone: 13311070920 Ms.Tracy Dai

- Technical Support

- E-Mail: support@bopixel.com

- PRODUCTS

- Structured Light 3D Camera

- High Speed Area Scan Camera

- HIGH SPEED LINE SCAN CAMERA

- DLP Projector

- Cr Series Code Reader & Industrial Smart Camera

- Ultra-high speed camera

- Line Laser 3D Profiler

- Frame Grabber

© 2023 Copyright Beijing BOPIXEL Technology Co., Ltd.Beijing Icp No. 2022013801